Substitute ASX Prospectus | INN

Highlights:

An preliminary quantity of 88m3 of concentrated eluate, which is the lithium carbonate an identical (LCE) of approx. one tonne, has been constituted of the Corporate´s DLE pilot plant in Copiapó, Chile over an working duration of 384 hours with 14 cycles finished

This completes the primary level of manufacturing from the DLE pilot plant

Effects display the DLE adsorbent completed a lithium restoration price of roughly 95% from the brine, with general restoration (adsorption plus desorption) reaching roughly 88%

Impurity rejection charges had been very prime generating a low impurity eluate conducive to the downstream conversion procedure.

The concentrated eluate is being shipped in 4 batches to the amenities of Conductive Power in Chicago, USA, for conversion into battery grade lithium carbonate

Cargo | Eluate Quantity | Eluate Li Grade | LCE (kg) | Cargo Standing |

1 | 24m3 | 2008 mg/L | 257 | Arrived procedure facility |

2 | 24m3 | 2360 mg/L | 301 | In Cargo |

3 | 24m3 | 2325 mg/L | 297 | In cargo |

4 | 17.5m3 | 2464 mg/L | 230 | At departure port |

Centered | 90m3 | 2000 mg/L | 1022 | |

General Accomplished | 88m3 | 2289 mg/L | 1085 |

Desk 1: Standing of concentrated eluate from pilot plant first level manufacturing

Conductive Power finished test-work on a 200L pattern of concentrated eluate shipped in Would possibly 2024 to optimise the downstream procedure ahead of receiving the bigger quantity shipments

The conversion test-work produced more than one samples of lithium carbonate with 99.75% lithium carbonate purity demonstrating that the method achieves goals and is repeatable

The result’s a primary affirmation {that a} procedure has been evolved that can successfully produce battery-grade lithium for the Laguna Verde mission from pilot scale DLE eluate

CleanTech Lithium is still a pacesetter in exploration and building of DLE based totally initiatives in Chile and this pilot scale manufacturing will supply huge check samples of lithium carbonate to doable offtake companions in search of product qualification.

Topic to the of completion of the re-injection smartly in September, the reserve file for Laguna Verde is scheduled to be finished via Sir Bernard Law and Mates in October 2024.

Steve Kesler, Govt Chairman and Period in-between CEO, of CleanTech Lithium PLC, stated:

“We’re very happy via those effects because it displays we will be able to produce battery-grade lithium with low impurities from our Laguna Verde brine mission. Running with our companions at the downstream procedure, Ahead Water and Conductive Power, we will be able to now reveal all of the DLE procedure from brine to ultimate lithium product.

“The optimised downstream procedure will now be implemented to the preliminary quantity of 88m3 of concentrated eluate, or roughly 1 tonne of LCE, constituted of the primary level of manufacturing from our DLE pilot plant. This may occasionally produce important check pattern volumes of battery-grade lithium carbonate for graduation of checking out with doable strategic companions. That is necessary while the Chilean executive is reviewing the feasibility of lithium initiatives to spot essentially the most complex firms in Chile and if they’re to succeed in their goal of getting 3 to 4 new lithium initiatives in building via 2026.”

Additional Knowledge

Pilot Plant in Copiapó First Level Manufacturing Finished

The Corporate´s DLE pilot plant is in Copiapó, Chile, roughly 275km from Laguna Verde. The plant completed commissioning in overdue March 2024 and up till mid-June a complete quantity of 1196m3 of brine from the Laguna Verde mission was once processed within the plant with a complete of 14 cycles finished. Each and every cycle represents a quantity of brine being fed first thru filtration to take away suspended solids, then into DLE columns which might be stuffed with adsorbent designed to be selective for lithium molecules. Lithium, as lithium chloride, is adsorbed from the brine, ahead of desorption with water to create a purified lithium chloride eluate. A opposite osmosis (RO) unit on the DLE pilot plant then concentrates the eluate via extracting roughly 75% of the water to shape a concentrated eluate.

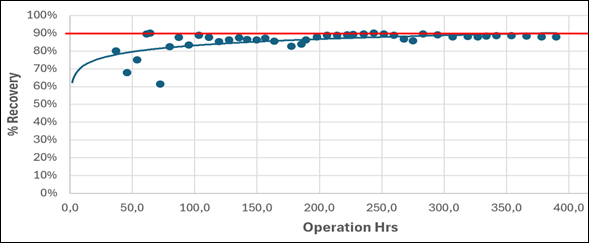

Averaged around the 14 cycles, the restoration price completed via adsorption of lithium via the adsorbent was once 95% and the restoration price of desorption from the adsorbent was once 93%. The entire restoration price averaged 88% and was once extremely constant as proven in Determine 1. The temperature of the brine and desorption water, the usage of the typical ambient temperature in Copiapó all the way through the March to June duration of operation, was once within the vary of 20oC to twenty-fiveoC, which failed to considerably have an effect on the restoration completed.

Determine 1: Pilot Plant General Restoration Price

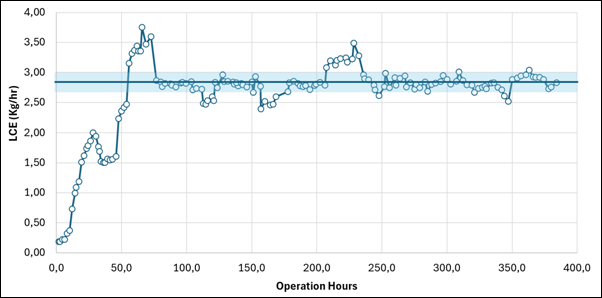

The eluate manufacturing price was once reasonably strong after the preliminary ramp up duration reaching a mean of two.8 kg LCE consistent with hour. The design of the plant is 1 tonne per thirty days of LCE in accordance with designed per month working time table of 360 hours. Because of finances and quantity issues, the plant was once run for 384 hours for the primary level of deliberate operation generating a complete of one.085 tonnes of LCE as eluate. In line with the hourly manufacturing price this met and exceeded the design capability of the plant.

Determine 2: Pilot Plant Manufacturing Price (Kg LCE/hr in Eluate)

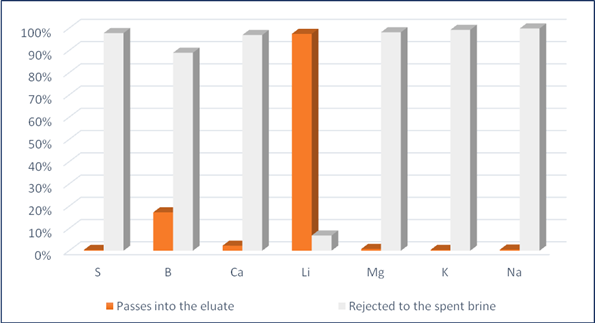

Selectivity of the adsorbent is every other key efficiency parameter for a DLE operation. DLE essentially acts as a purification level, convalescing lithium chloride from the brine while rejecting different impurities. For the entire main ions within the brine, aside from boron, the rejection price was once very prime as proven in Fig. 3 beneath. Extra cycles will additional validate this efficiency. The standard of the eluate was once constant over the primary level of manufacturing with the low degree of impurities facilitating downstream conversion.

Determine 3: DLE Efficiency – Rejection of Main Impurities

After of completion of the DLE level, the eluate is targeted the usage of a opposite osmosis (RO) unit on the pilot plant. On of completion of each phases the lithium grade within the purified lithium chloride eluate is over ten instances upper than the feed brine. The concentrated eluate was once then loaded right into a flexitank in a normal transport container and transported to the port of Caldera for cargo to North The united states.

Downstream Processing into Battery Grade LithiumCarbonate: Check-work Finished

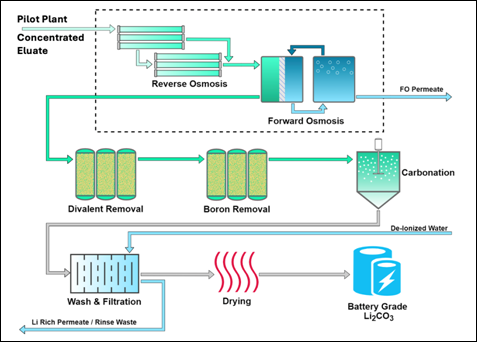

For the conversion of the concentrated lithium chloride eluate into battery grade lithium carbonate, CleanTech Lithium has engaged a number one lithium processing corporate, Conductive Power, based totally in Alberta, Canada, which has amenities in Chicago, USA, with key downstream processing devices proven in Determine 4 beneath. The standing of the concentrated eluate cargo is proven in Desk 1 with processing to start in August 2024.

|

|

Determine 4: Conductive Power Carbonation Reactor Tank and Apparatus for Washing, Filtering & Drying

In Would possibly 2024 CTL air-freighted a 200L pattern of concentrated eluate from the pilot plant to Conductive Power to adopt test-work to optimise the conversion procedure. The method steps are proven in Determine 5, involving an additional level of RO, ahead of the usage of Ahead Osmosis (FO) to succeed in an overly prime degree of focus. Ion alternate (IX) is used to take away calcium, magnesium, and boron. The general steps are carbonation after which washing, filtration and drying to supply a battery grade product. Conductive Power´s means is to simplify the method that achieves most yield via minimizing procedure steps and, the place losses happen, produce fluids which might be simply recycled to additional maximize yield.

Determine 5: Conductive Power Conversion Procedure

Opposite Osmosis and Ahead Osmosis

The rise in eluate and lithium focus within the R/O and F/O phases are proven in Desk 2 beneath. R/O is efficacious for focus till General Dissolved Solids (TDS) succeed in the extent of roughly 60,000 – 70,000 TDS, and then it’s an increasing number of power extensive and dear. F/O is very efficient in additional focus to the specified lithium grade for carbonation, on this case 18,000mg Li/L (or 1.8% Lithium). The F/O unit is equipped via Ahead Water Era, every other Canadian corporate based totally in Ontario. F/O achieves a prime focus issue with a lot decrease power use than the other of the usage of a mechanical evaporator, whilst being extremely appropriate for utilising sun thermal because the power supply to energy the F/O procedure.

Parameter | Unit | Concentrated Eluate | R/O Pay attention | F/O Pay attention |

Lithium (Li) | mg/L | 2,194 | 5,700 | 18,000 |

Chloride (Cl) | mg/L | 11,039 | 37,000 | 110,000 |

Boron (B) | mg/L | 411 | 850 | 1,700 |

Calcium (Ca) | mg/L | 7 | 29 | 85 |

Magnesium (Mg) | mg/L | 14 | 50 | 150 |

Sodium (Na) | mg/L | 134 | 400 | 1,400 |

Sulphate (SO4) | mg/L | 103 | 120 | 330 |

General Dissolve Solids (TDS) | mg/L | 19,260 | 62,000 | 190,000 |

Quantity | L | 215.5 | 66.3 | 13.9 |

Aid in Quantity | % | 69.3% | 93.5% | |

Laboratory | ALS Chile | Lambton.Medical | Lambton.Medical |

Desk 2: Effects from focus of Laguna Verde eluate thru R/O adopted via F/O

Ion Change to Take away Impurities

Ion alternate (IX) was once used for elimination of calcium and magnesium, which completed 85% and 87% discounts respectively. Whilst feed concentrations had been low, 100% of barium and manganese had been additionally got rid of in the similar procedure. Further optimization is conceivable with doable for additional calcium elimination. Lithium loss was once low at 3%.

Conductive then implemented its optimised IX for elimination of boron. This was once extremely efficient reaching >99.5% elimination of boron. On the other hand, there was once a 22% lack of lithium to the regeneration fluid. This might be recaptured via recycling the regeneration fluid to the F/O feed which was once now not carried out for this small-scale test-work. The lithium loss from the boron IX is anticipated to be lowered (recovered) to a gentle state loss price of about 3%.

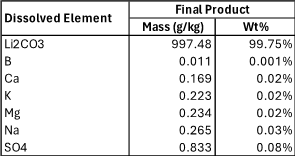

Carbonation and Battery Grade Lithium Pattern

The carbonation test-work completed an outstanding yield of 96% of the theoretical most. The general product, after the wash process, was once 99.75% lithium carbonate purity as proven in Desk 3. Additional optimisation of the bathing level is deliberate as a way to cut back impurities to the best extent conceivable and due to this fact maximise the price of the battery grade product.

|

|

Desk 3: Procedure test-work lithium carbonate pattern purity Fig. 6: Check-work pattern

Further Operations

Laguna Verde Reserve File Replace

The following level of useful resource analysis on the Laguna Verde mission is to supply an up to date JORC compliant useful resource and a reserve file in accordance with changing a portion of sources into reserves. The control of the useful resource analysis programme and reserve file is led via Sir Bernard Law and Mates, a number one hydrogeology guide with in depth enjoy in useful resource analysis of lithium brine initiatives in Chile and Argentina. Reserve estimation will feed immediately into the Pre-Feasibility Find out about which is concentrated for later this 12 months.

The reserve calculation calls for the of completion of pumping assessments and a re-injection smartly on the mission which is scheduled for September 2024, when drilling apparatus can also be re-mobilised after the present iciness wreck in operations. Topic to the of completion of the re-injection smartly in September, the reserve file is scheduled to be finished via Sir Bernard Law and Mates in October 2024.

Competent Individuals

The next skilled acts as certified particular person, as outlined within the AIM Observe for Mining, Oil and Gasoline Corporations (June 2009) and JORC Code (2012):

Marcelo Bravo: Chemical Engineer (Universidad Católica del Norte), has a Grasp’s Level in Engineering Sciences main in Mineral Processing, Universidad de Antofagasta. He these days works as a Senior Procedure Consulting Engineer on the Advert-Infinitum corporate. Mr Bravo has related enjoy in researching and creating potassium, lithium carbonate, and sun evapo-concentration design processes in Chile, Argentina, and Bolivia. Mr Bravo, who has reviewed and licensed the tips contained within the chapters related to his experience contained on this announcement, is registered with No. 412 within the public registry of Competent Individuals in Mining Assets and Reserves consistent with the Regulation of Individuals Competent and its Laws in pressure in Chile. Mr Bravo has enough enjoy related to the metallurgical assessments and the kind of next processing of the extracted brines into account and to the task being performed to qualify as a reliable particular person, as outlined within the JORC Code. Mr Bravo concurs to the inclusion within the press unlock of the issues in accordance with his data within the shape and context by which it sounds as if.

The ideas communicated inside of this announcement is deemed to represent inside of data as stipulated below the Marketplace Abuse Laws (EU) No 596/2014 which is a part of UK regulation via distinctive feature of the Eu Union (Withdrawal) Act 2018. Upon newsletter of this announcement, this inside of data is now regarded as to be within the public area. The one who organized for the discharge of this announcement on behalf of the Corporate was once Gordon Stein, Director and CFO.

For additional data touch: | |

Steve Kesler/Gordon Stein/Nick Baxter | Jersey place of business: +44 (0) 1534 668 321 Chile place of business: +562-32239222 |

Or by the use of Celicourt | |

Celicourt Communications Felicity Winkles/Philip Dennis/Ali AlQahtani | +44 (0) 20 7770 6424 |

Beaumont Cornish Restricted (Nominated Adviser) Roland Cornish/Asia Szusciak | +44 (0) 20 7628 3396 |

Fox-Davies Capital Restricted (Joint Dealer) Daniel Fox-Davies | +44 (0) 20 3884 8450 |

Canaccord Genuity (Joint Dealer) James Asensio | +44 (0) 20 7523 4680 |

Beaumont Cornish Restricted (“Beaumont Cornish”) is the Corporate’s Nominated Adviser and is authorized and controlled via the FCA. Beaumont Cornish’s tasks because the Corporate’s Nominated Adviser, together with a duty to advise and information the Corporate on its tasks below the AIM Laws for Corporations and AIM Laws for Nominated Advisers, are owed only to the London Inventory Change. Beaumont Cornish isn’t performing for and might not be accountable to every other individuals for offering protections afforded to shoppers of Beaumont Cornish nor for advising them with regards to the proposed preparations described on this announcement or any topic referred to in it.

Notes

CleanTech Lithium (AIM:CTL, Frankfurt:T2N, OTCQX:CTLHF) is an exploration and building corporate advancing sustainable lithium initiatives in Chile for the blank power transition. Dedicated to net-zero, CleanTech Lithium‘s project is to supply subject matter amounts of sustainable battery grade lithium merchandise the usage of Direct Lithium Extraction generation powered via renewable power. The Corporate plans to be a number one provider of ‘inexperienced’ lithium to the EV and battery production marketplace.

CleanTech Lithium has two key lithium initiatives in Chile, Laguna Verde and Viento Andino, and hang licences in Llamara and Salar de Atacama, situated within the lithium triangle, a number one centre for battery grade lithium manufacturing. The 2 main initiatives: Laguna Verde and Viento Andino are positioned inside of basins managed via the Corporate, which offers important doable building and operational benefits. All 4 initiatives have direct get right of entry to to present infrastructure and renewable energy.

CleanTech Lithium is dedicated to the usage of renewable energy for processing and decreasing the environmental have an effect on of its lithium manufacturing via utilising Direct Lithium Extraction with reinjection of spent brine. Direct Lithium Extraction is a transformative generation which eliminates lithium from brine, with upper recoveries than standard extraction processes. The process provides quick building lead instances with out a in depth web page development or evaporation pond building so there’s minimum water depletion from the aquifer. www.ctlithium.com

**ENDS**

This data is equipped via RNS, the scoop provider of the London Inventory Change. RNS is licensed via the Monetary Habits Authority to behave as a Number one Knowledge Supplier in the UK. Phrases and stipulations when it comes to the use and distribution of this data might observe. For additional data, please touch rns@lseg.com or discuss with www.rns.com.

SOURCE: CleanTech Lithium percent

View the unique press unlock on accesswire.com